Email:gwdlcom@gmail.com |

sales@gwdl.com

Telephone/WhatsApp:+86-15637962277

1.1 classification of titanium alloys

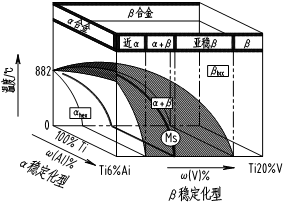

Titanium alloys can be divided into three categories. The 3d phase diagram of titanium alloy classification is a relatively obvious schematic diagram, as shown in figure 1.

α T-titanium alloy, including industrial pure titanium, TA5(ti-4al-0.005b), TA7(ti-5al-2.5 Sn), etc. This kind of alloy can not be strengthened by heat treatment, can only be annealed, stable structure, low strength at room temperature.

Proximal α titanium alloy, which contains a small amount of highly stable elements (2%) and a phase of 7% to 15% in the β structure, such as material grades: TC1(ti-2al-1.5 Mn) and TC2(ti-4al-1.5 Mn), is not sensitive to the heat treatment system.

α+β titanium alloy, also known as martensite + homo-type titanium alloy, containing 15%-40% β phase, typical representative material TC4(ti-6al-4v), thermal strength titanium alloy TC6(ti-6al-2.5 mo-1.5 cr-0.5 fe-0.3 Si), typical representative material TC16(ti-3al-5mo-4.5 V) for fasteners, they can be strengthened by torsion-star heat treatment, namely: solid solution treatment + aging (dispersion strengthening).

Sub - stable - β type titanium alloy, the material contains critical concentration of highly β stable elements. This kind of alloy has good workability, annealed can strengthen, heat treatment after quenching and aging treatment can achieve high intensity, metastable beta titanium alloy at room temperature strength, fracture toughness and hardenability is superior to the alpha + beta titanium alloy, typical materials of TB2 (Ti - 5-8 cr mo - 5 v - 3 al), TB5 (Ti - 3-15 v cr - 3 sn - 3 al) and TB8 (Ti 15 mo - 3 - al - 2.7 - Nb - 0.2 - Si), TB8 21 s (beta) titanium alloy for high strength titanium alloy, high-temperature performance is good, With excellent cold rolling and cold-forming properties, it is recognized as a high strength spring material for aircraft.

After the content of stabilized β titanium Alloy exceeds a certain value, the transition temperature will drop below room temperature. The metallographic structure is a single-β phase structure, which represents the American Alloy C (ti-35v-15cr).

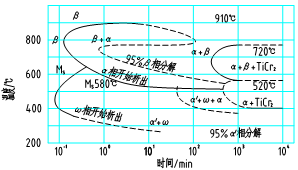

1.2 phase transition during cooling of titanium alloy

After the titanium alloy is heated in a vacuum furnace, the cooling phase change process of the titanium alloy parts is precisely controlled to obtain different structures. The basis of the enhanced heat treatment is the titanium alloy heating and cooling phase transition, titanium alloy from high-temperature rapid cooling, martensitic phase transition, the β phase can be converted to martensitic (hexagonal martensitic α or rhombic martensitic α "), ω phase or subcooled β phase (i.e. Taking ti-5cr-3al titanium alloy as an example [5], the metastable β phase isothermal transformation process is illustrated, as shown in FIG. 2.

As can be seen from FIG. 2, during cooling, the β phase changes. If the process is to obtain martensitic transformation, the cooling rate must be increased. And β goes to α '(HCP, martensite).When the cooling speed is slow (cooling in oil), part of the β →ω phase (triangular structure); When the cooling rate is lower (pressure air cooling), flat β→α'+ω, When the cooling rate is very low (air cooling), β phase→α+β In the range of 520 ℃ to 720 ℃, eutectoid decomposition occurs when the cooling rate is very slow (or under the eutectoid temperature for a long time), that is, the β phase nucleates and α phase grows in the original β phase boundary.

Therefore, to realize the heat treatment strengthening of titanium alloy materials, quenching is the necessary prerequisite for the heat treatment strengthening of titanium alloy, and the cooling rate of the quenching process is the decisive factor.

1.3 strengthening characteristics of heat treatment of titanium alloy

Titanium alloys undergo phase transition during heating and cooling, and different structures can be obtained by controlling the phase transition process of different alloy systems. According to the cooling test of titanium alloy in different media, it can be found that the heat treatment strengthening characteristics of titanium alloy are as follows:

(1) the quenching process should try to avoid the formation of ω phase,ω phase meet materials become brittle, of course, using high-temperature aging can make ω phase decomposition;

(2) repeated heat treatment cannot refine the grain of titanium alloy, which is different from that of iron and steel materials;

(3) alpha + beta type titanium alloy after heat treatment quenching hardenability is not high, quenching heat stress is big, very easy cause long rod parts deformation, therefore the long rod workpiece can only in the vertical loading charging heating, and the longitudinal into the quenching medium, based on the research and development of reduce the workpiece deformation of vertical vacuum quenching furnace to appropriately reduce the quenching deformation of titanium alloy heat treatment process provides conditions;

(4) the martensitic phase transformation cannot strengthen the titanium alloy, and it can only be obtained through the aging decomposition of the stable phase (including the martensitic phase) formed during quenching, that is, diffusion strengthening. The heat treatment strengthening is not effective to the α titanium alloy, the heat treatment strengthening is mainly used for the α+β titanium alloy and the β titanium alloy.