Email:gwdlcom@gmail.com |

sales@gwdl.com

Telephone/WhatsApp:+86-15637962277

Abstract

The rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a batch process. The basic components of a rotary kiln are the shell, the refractory linings, support tires (riding rings) and rollers, drive gear, and the heating elements. GWL has designed different solutions according to the needs of different customers. GWL is particularly good at sintering powder and particles containing water and organic matter in products with relatively rich production experience.

WorkFlow

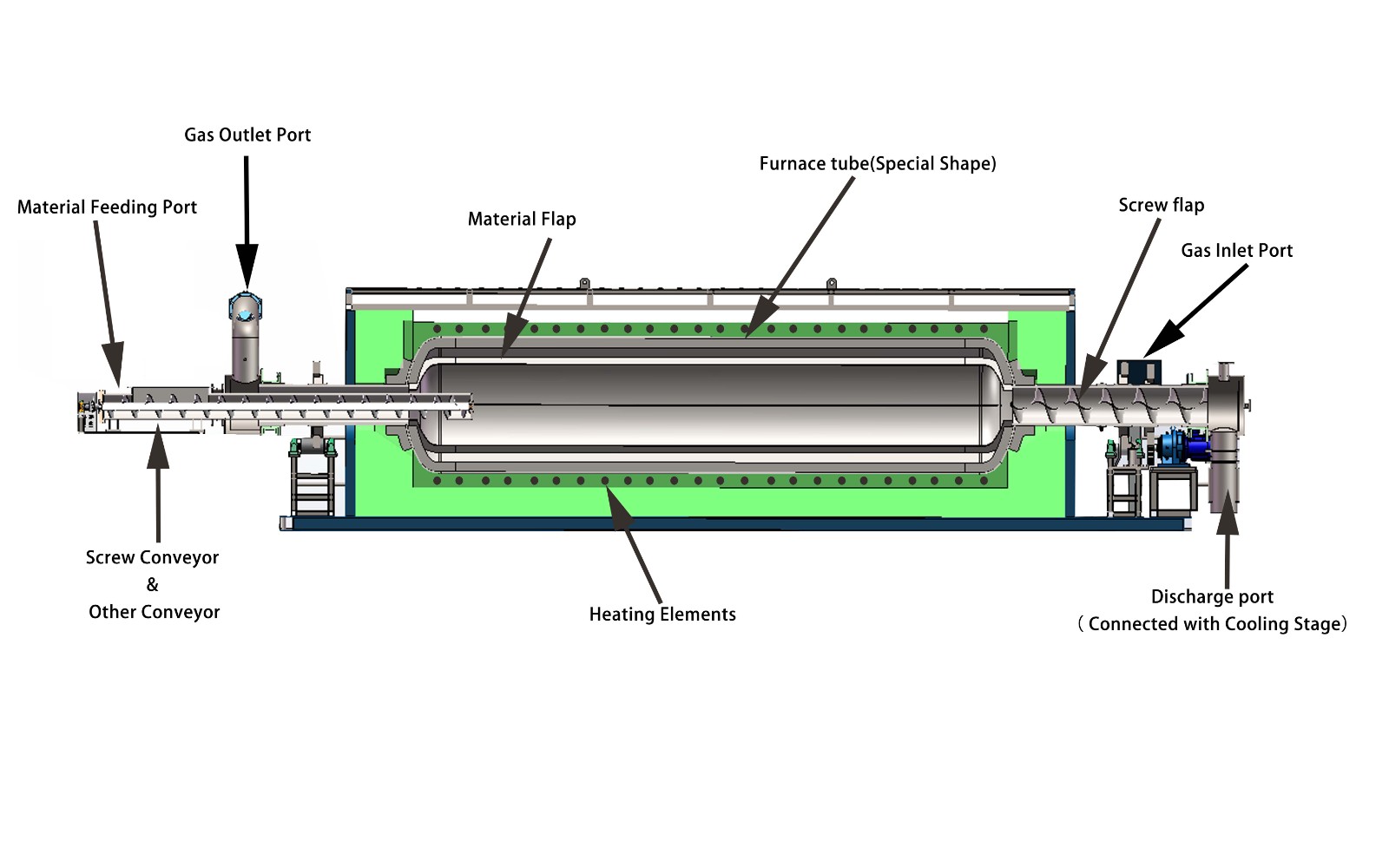

The rotary kiln's tube is a cylindrical vessel, Horizontal installation, which is rotated slowly about its longitudinal axis(Controlled by a rotating motor). As the kiln rotates, the material is heated through the furnace tube during rotation and may undergo a certain amount of stirring and mixing. Using the electric resistance heating method to heating the materials, and once the process completed, Control the lifting Angle of the furnace body after heating, the material can be discharged to the cooling section.

Rotary Kiln Working Principles

Conveying materials of different properties through screw feeder (variable frequency control) into rotary kiln's tube, The anisotropic design of the furnace tube increases the filling rate of material, As the tube rotates and the furnace tube flap, the material will automatically fall into the tube and pile up at the end. Customers can make corresponding Settings according to their own heating process. The furnace will heat up by itself according to the parameters set. After heating up, The tilting Angle can be adjusted through PLC for discharging operation. If the discharge temperature is too high, the tail can be considered to add a cooling section (water spray or other cooling methods can be customized).

Electric control cabinet

According to customers' different budgets, GWL provides different types of electric control cabinet combinations, with protection classes ranging from IP46 to IP65, to avoid the adverse effects of dust and dust in the air on the electric control cabinet. The selection of electrical components ranges from the mainstream first-tier and second-tier brands, from Siemens and ABB to domestic brands such as Anton and yudian. Different customer groups can meet customer needs.

Control system

GWL offers a wide range of control systems, from basic touch screen controls to fully automated controls in industry 4.0. In the process of automation, emergency stop protection is provided, as well as emergency treatment measures for various emergencies. After addressing the user convenience, focus on security. According to different customer processes, customers can set up in a simple operation interface and get the running status at any time.

Standard features

1700°C maximum operating temperature

Kiln tube diameter( Metal tube maximum 800MM, The quartz tube&alumina tube maximum 400mm)

Kiln tube Length(Can be customized base on customer's production process)

Double layer furnace shell air cooling ensures the surface temperature less than 45℃

Vacuum formed, low thermal mass insulation

Silicon carbide rod or silicon molybdenum rod fitted as standard

Double layer protection(over current, over temperature and over voltage, etc

Incline degree(0-5° can be customized, Fixed during installation and debugging)

With stepless speed change, the speed of rotation can be controlled

Heating zone length and quantity can be customized

Options (specify these at time of order)

Control software and system.

Multi-face heating

Anti-corrosion

Multi-temperature control

Vacuum requirements

Design conditions(Customers need to give answers, design needs to refer to the following answers)

Rotary kiln is not a standard product, so it needs to be designed according to the customer's process requirements.GWL will carry out detailed design according to the output requirements provided by the customer, as well as the specific gravity of the sintering material, and the use temperature, so as to ensure that every link conforms to the scientific basis. And according to the customer sintering process to make reasonable Suggestions, at the same time to consider the conditions of environmental protection, according to different requirements, we have different design schemes.

The density of the material which you want to Sintering?

Daily or per year how many final materials you want to get from the kiln?

The material calcination temperature curve (temperature rise and cooling curve)?

Furnace surface temperature uniformity (top middle bottom)?

Is it any volatile during the process?

Product vibration requirements for mechanical motion or transmission?

Atmosphere requirements?

Material feeding and discharge method?

Requirements and methods for soot emissions and disposal?

Product Usage

Rotary kiln can be used for municipal waste incineration (need to be equipped with exhaust gas purification furnace), powder sintering with large production requirements, particulate sintering with large production requirements. It can be used for the sintering processing of various raw materials, especially for batteries and the new energy industry.

*Content may be subject to modifications or corrections