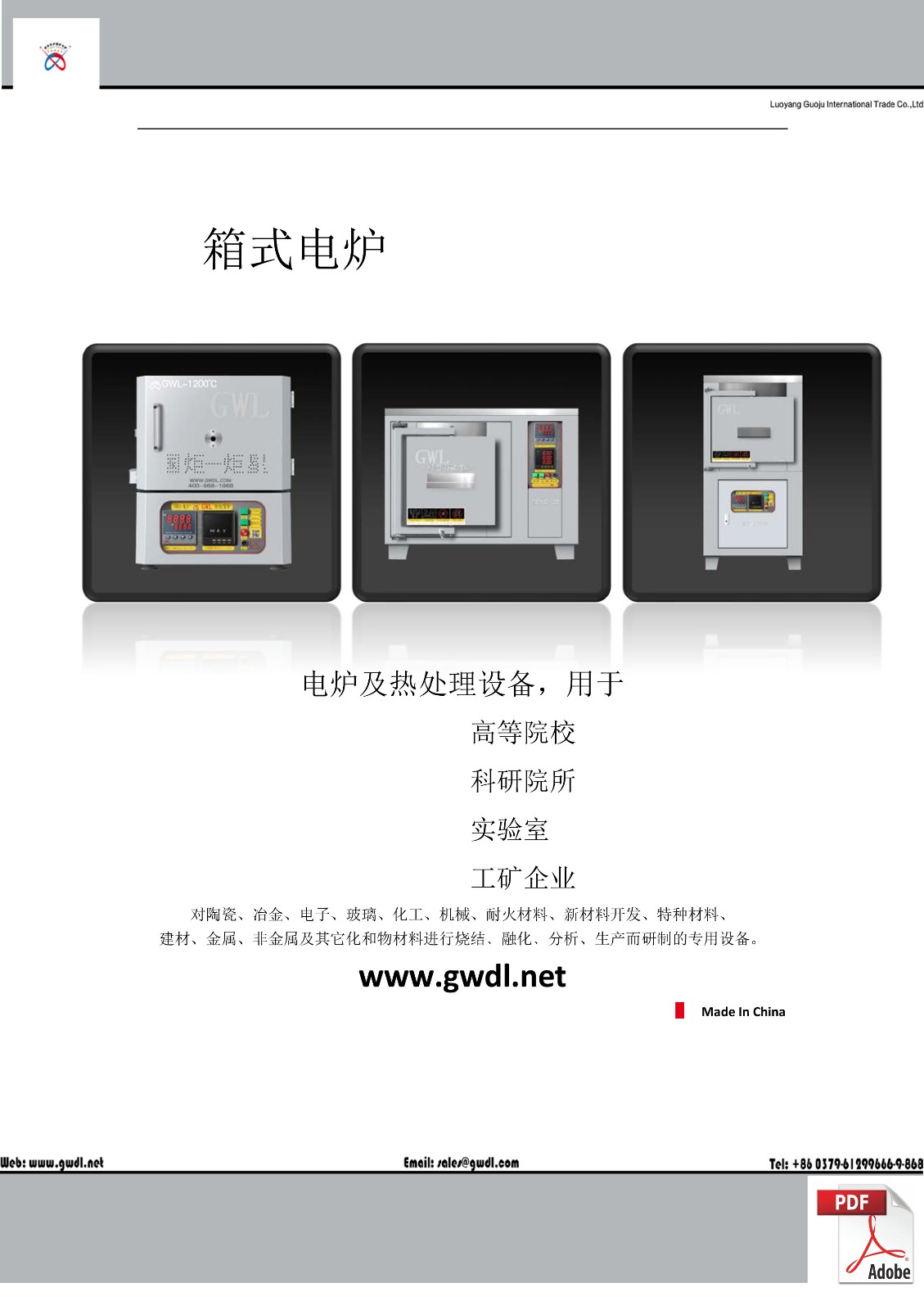

| Product Name | Resistance Furnace/Box-type Electric Furnace/Muffle Furnace | Product Name | Resistance Furnace/Box-type Electric Furnace/Muffle Furnace |

| Model | GWDL-XL | Specification | 1400℃ |

| Maximum Operating Temperature | 1400℃ | Long-term Operating Temperature | 1300℃ |

| Furnace Chamber Size | 300300300mm | Effective Temperature Range | 600-1300℃ |

| Voltage | 380V±15% | Temperature Control Range | 50-1400℃ |

| Power | 18kw | Temperature Control Accuracy | ±1℃ |

| Equipment Appearance Color | Signal White (RAL9003) | Constant Temperature Accuracy | ±5℃ |

| Temperature Measuring Element | S-type dual-core thermocouple (complying with AMS2750H), brand: Chongqing Dazheng | Furnace Temperature Uniformity | ±5℃ |

| Alarm Instrument | Yokogawa (Japan) UM33A-010-11/CV/CT/Z | Heating Element Material | Kanthal imported resistance wire |

| Temperature Control Instrument | Yokogawa (Japan) UP55A-021-11-00/AP/HA/CT | Heating Element Installation Position | Around the furnace + bottom of the furnace |

| Papery Recorder | Dahua Chino 4700 series (accuracy meets the configuration requirements of AMS2750H Class Ⅰ heating furnace) | Heating Rate | Maximum heating rate: 20℃ per minute (non-linear); Minimum heating rate: 1℃ per hour |

| Furnace Body Structure & Material | The electric furnace body adopts an air-cooled double-layer carbon steel structure. The effective air-cooled guide baffle enables the overall cold air circulation of the furnace shell, and finally cools the conductive sheet of the heating element and then discharges it out of the furnace body, avoiding the high-temperature oxidation of the conductive sheet of the heating element and ensuring a good working environment. | Door Opening Method | The furnace door can be opened 180° sideways. The furnace door lock is located on the side of the furnace door and is equipped with an elastic lock, which can effectively lock the door. The elasticity of the lock absorbs the expansion of the refractory material, ensuring the free expansion and contraction of the refractory material due to thermal expansion and cold contraction and effective sealing. |

| Refractory & Thermal Insulation Material | The furnace lining is made of vacuum-formed high-purity alumina lightweight material, which has high operating temperature, small heat storage, resistance to rapid heating and cooling, no cracking, no slag dropping, and good thermal insulation performance. | Safety Protection | It adopts an integrated module control unit with accurate control accuracy, and is designed with dual-circuit control and dual-circuit protection. It has protections against overshoot, overregulation, underregulation, thermocouple breakage, phase loss, overvoltage, overcurrent, overtemperature, current feedback, soft start, etc. |

| Power-off on Door Opening | The furnace body is designed with the function of disconnecting the main heating circuit when the high-temperature furnace door is opened during operation, which greatly reduces the risk of electric shock when taking materials at high temperature. | Safety Temperature Control | It adopts closed-loop technology for thyristor module trigger control, phase-shift trigger control or zero-crossing trigger mode. The output voltage, current or power is continuously adjustable, with the characteristics of constant voltage, constant current or constant power. The current loop is the inner loop and the voltage loop is the outer loop. When a sudden load is applied or the load current exceeds the current limit value, the output current of the voltage regulator is limited within the rated current range to ensure the normal operation of the output and the voltage regulator. At the same time, the voltage loop also participates in the regulation, so that the output current of the voltage regulator is limited within the rated current range, and the output current and voltage are maintained constant under the premise of sufficient adjustment margin. Thus, the heating element is protected from the impact of excessive current and voltage, and safe and reliable control effect and control accuracy are achieved. |

| Temperature Curve Setting | It adopts an intelligent temperature controller, with multiple regulation modes such as standard PID, artificial intelligence regulation APID or MPT. It has self-tuning and self-learning functions, and excellent control characteristics of no overshoot and no underregulation. It is equipped with 30-segment program control function, which can realize heating and cooling control with any slope. It has programmable/operable commands such as jump (cycle), run, pause and stop, and allows modifying the program at any time during the controlled operation of the program. It adopts an artificial intelligence regulation algorithm with curve fitting function, which can obtain a smooth and smooth curve control effect. | Number of Heating Curve Segments | 30-segment program control function. The input settings are as follows: one curve with 30 segments, two curves with 28 segments each, three curves with 15 segments each, and five curves with 9 segments each. Multiple curves can be input at the same time and can be called arbitrarily during use. |

| Panel Buttons | Two buttons/knobs: main power button/knob, heating chamber on button/knob | Random Accessories | One set of heating elements, one dual-core S-type thermocouple (matching the equipment), one crucible tongs, one pair of high-temperature gloves, one furnace bottom pad |