Email:gwdlcom@gmail.com |

sales@gwdl.com

Telephone/WhatsApp:+86-15637962277

A vacuum heat treatment furnace is a device used for thermal processing under oxygen-free or low-oxygen conditions. It achieves controlled heating and cooling of materials at high temperatures by establishing a vacuum environment in the furnace chamber and removing oxygen and other harmful gases.

A vacuum heat treatment furnace typically consists of a sealed furnace chamber and a vacuum system. During the heating process, the pressure inside the furnace chamber is reduced to extremely low levels, minimizing the oxygen content in the atmosphere to prevent material oxidation and reactions. By controlling the heating temperature and maintaining a vacuum environment, the vacuum heat treatment furnace enables precise control of materials, including processes such as annealing, quenching, and tempering.

Vacuum heat treatment furnaces are widely used in the thermal processing of metallic materials, such as steel, stainless steel, and titanium alloys. They can improve the mechanical properties, corrosion resistance, and microstructure of materials, resulting in higher strength, hardness, and wear resistance. Additionally, vacuum heat treatment furnaces are employed in fields such as ceramics, electronic components, and powder metallurgy for thermal processing applications.

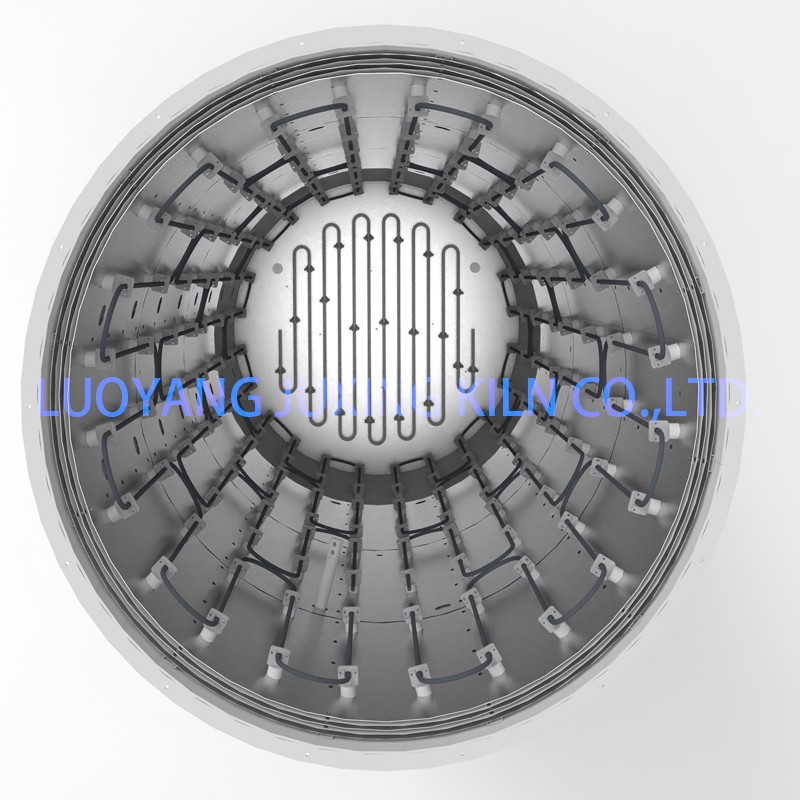

Metal furnace & reflection screen diagram

*It is essential to discuss your application with us to ensure the suitability of the material for use in this equipment.

Standard features

2200 °C maximum operating temperature; normal operating temperature range 600 °C - 1650 °C

Furnace chamber dimensions can be customized according to customer needs.

Vacuum up to 0.0001Pa negative pressure.

The gas paths and control mode can be customized according to customer needs.

Stainless steel & Molybdenum heating elements & Tungsten heating elements are available.

The reflective screen material can be combined according to different heating elements

PID & PLC Control can be chosen.

Options (specify these at the time of order)

Mass flowmeter, digital display vacuum meter, etc., available

Available options for refrigeration units

*Content may be subject to modifications or corrections