Email:gwdlcom@gmail.com |

sales@gwdl.com

Telephone/WhatsApp:+86-15637962277

Silicon carbide rod made from high purity silicon carbide as main material, According to a certain ratio of the material for doing the process making the rough-cast,after 2200 ℃ high-temperature recrystallization silicide sintering to rod-shaped, tubular non - metal high - temperature electric heating element. under an oxidizing atmosphere, the normal using temperature can reach 1450 ℃,Continuous use around 2000 hours. Silicon carbide rod it has high using temperature,it has high-temperature resistance、oxidation resistance、corrosion resistance、fast temperature rise rate、Long using life、Less high-temperature deformation、convenient installation and maintenance, it also has the excellent chemical stability。

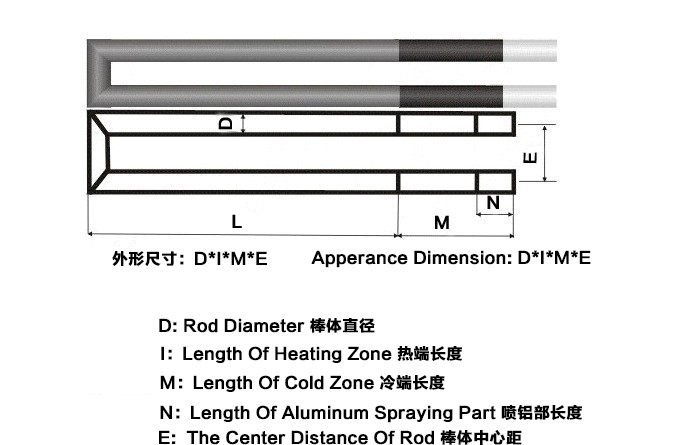

Model Of Silicon Carbide Rod

Our Company Can Offer "M" Shape Type, "U" Shape Type, "H" Shape Type And Vertical Type Silicon Carbide Rod, Customer can inquire base on the furnace needs.

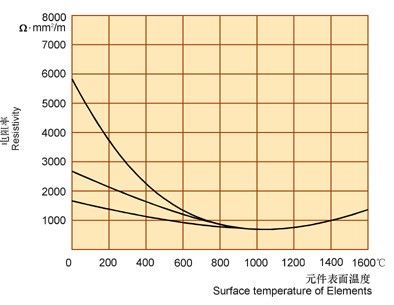

The Electric Appliance Performance Of Silicon Carbide Rod

Silicon carbide rod it has the large Specific Resistivity, When Heating under air atmosphere, Heating part surface temperature around 1050±50℃, The Resistivity is 600-1400Ω-mm2/M. The resistance of the silicon carbide rod will be increased during the temperature changes, From indoor temperature to 800℃. The resistance temperature characteristic curve is negative values, Temperature above 800℃ is positive values.

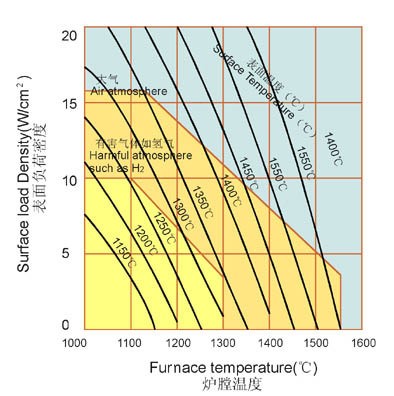

The Load Of Silicon Carbide Rod Surface

The Load Of Silicon Carbide Rod Surface=Rated Power/ Heating part surface Proportion(W/cm2)

A load of silicon carbide rod surface will be influencing the using life circle, that is why, When the electricity is heated, it should be strictly controlled within the allowable load range and should not be overloaded. Silicon carbide rod heating part surface temperature and each furnace temperature, heating part surface allowed load has given below.

Effect of atmosphere on silicon carbide.

The different gas atmosphere will influence the silicon carbide rod using life, During the process of using the Silicon carbide will be gradually oxidized to SiO2, Separation of SiC crystalline particles, increase the local resistance, volume expansion, and finally break. Silicon carbide heating elements in continuous use of clean air drying (1450℃) life up to 2000 hours.

Atmosphere | Maximum Working Temperature(℃) |

Air | 1600 |

Vacuum | 1000-1200 |

Nitrogen | 1350 |

Hydrogen | 1200 |

Hydrocarbon | 1250 |