Email:gwdlcom@gmail.com |

sales@gwdl.com

Telephone/WhatsApp:+86-15637962277

GWDL-FB series ceramic fiberboard (inorganic board) is composed of spray fiber (short, fine, easy to break and mix) as the raw material of ceramic fiberboard, adding a certain proportion of binder, filler grade additives, after beater, fully dispersed into slurry in the slurry pool. Pump into the forming tank and stir with compressed air. The mold is put into the forming pool, and the fiber slurry is adsorbed on the mold by the principle of vacuuming. Accurately control the adsorption time, vacuum dehydrates the wet fiber material, releases the mold, put it on the tray, and sends it to the drying furnace for 10-24 hours. After drying fiberboard through the special grinding machine, cutting machine, precise control of size.

After the fiberboard is formed, it will undergo preliminary calcination to remove organic matter in the product, reduce the shrinkage effect of high temperature on the product, and improve the service life of the product. The GWDL-FB-1800 fiberboard and special shaped products can long-term serve at 1750℃ and at 1800℃ of the maximum and have been used in many kilns to substitute imported products, saving energy and cutting costs.

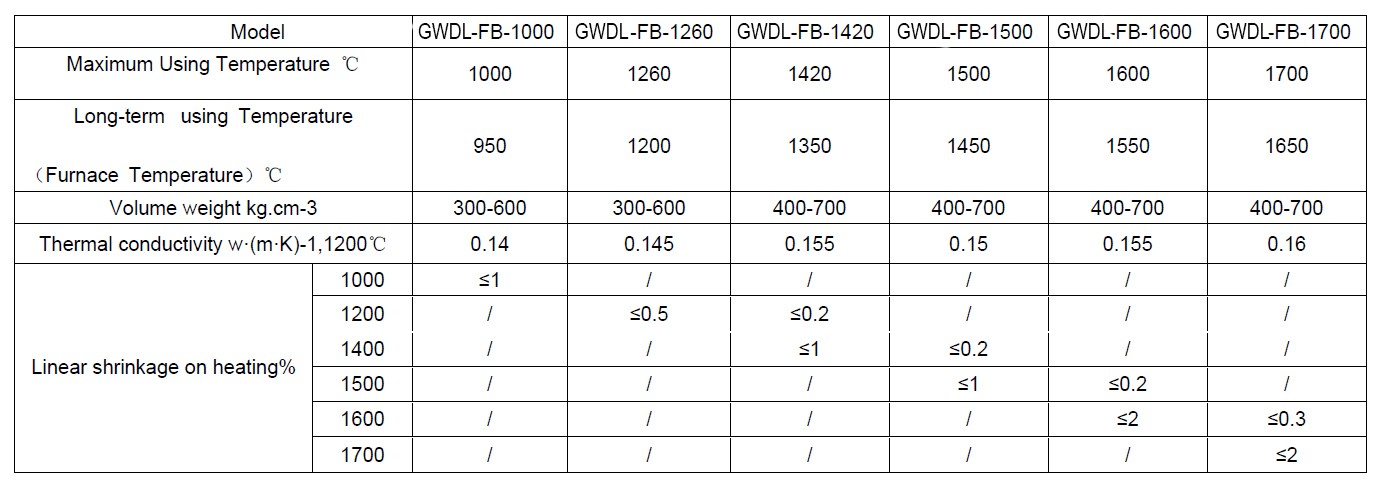

Product specification

Application

Used as thermal and electric insulating materials for high-temperature electric furnaces and heating units of equipment, and lining materials for tunnel kiln and roller kiln

Product specification: Standard dimension:1000×600×50( mm)(Length * width * thickness)

Remark: Product technique data are an average value base on standard tests, it will fluctuate in a certain range, is not the quality assurance data of the product.